Alloy – Positive Material Identification (PMI)

Industry Specific Applications

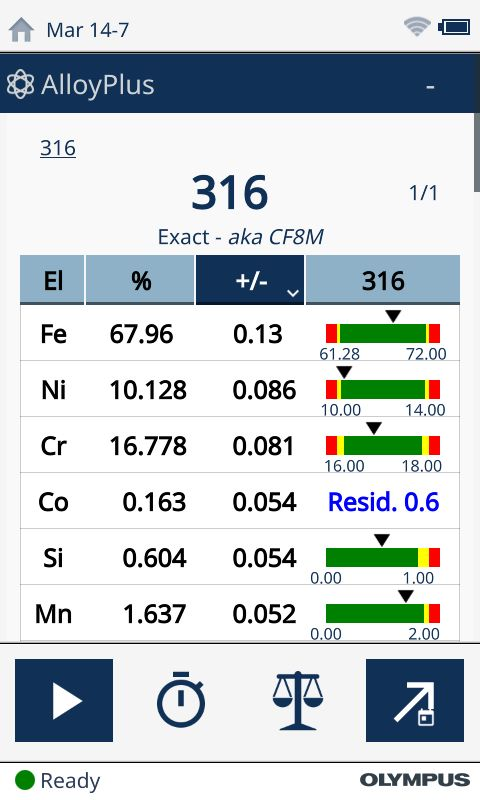

XRF (X-Ray Florescence)

Accurate Chemistry and Alloy ID

Handheld XRF analysers provide fast, accurate chemistry and alloy identification in PMI applications including piping, valves, welds, components, and pressure vessels.

- Ensuring the correct alloy components are installed in critical locations.

- Complying with American Petroleum Institute (API) Recommended Practice (RP) 578—Material Verification Program for New and Existing Alloy Piping Systems.

- Detecting sulfidation corrosion susceptibility (API RP 939-C).

- Evaluating flow accelerated corrosion (FAC) susceptibility.

- Discerning residual element corrosion susceptibility in hydrofluoric acid (HF) alkylation units.

- Cloud technology enabled.

Material Compliance Programs

Safety Throughout the Supply Chain

In modern industrial environments, XRF analysers are vital for material compliance programs and helping to ensure safety throughout the supply chain. With the optional panoramic camera, permanent records are instantly created on PDF reports, which can further be used in the Quality departments.

Vanta handheld XRF analysers accurately and repeatedly detect and quantify:

- Residual Elements (RE) in low alloy and carbon steels

- Trace silicon (Si) in carbon steel per API RP 939-C

- Sulfur (S) and phosphorus (P) for in-service stainless steels

OES (Optical Emission Spectroscopy)

Belec Compact Port HLC

Portable hybrid spectrometer for metal analysis

The Belec Compact Port HLC is the world's only portable hybrid spectrometer for metal analysis for perfect analysis of carbon combined with best and unique flexibility and latest 6GSO-System.

What has only been known from huge laboratory spectrometers, now comes true also in our latest portable spectrometer generation.

- latest state-of-the-art detectors, developed for spectroscopy application.

- easy handling

- mobility by trolley

- user friendly Software Belec Win 21

- analysis of C, P & S with Argon Probe

- analysis of Nitrogen in Duplex steels, optional

- high accuracies (C from 0.003%)

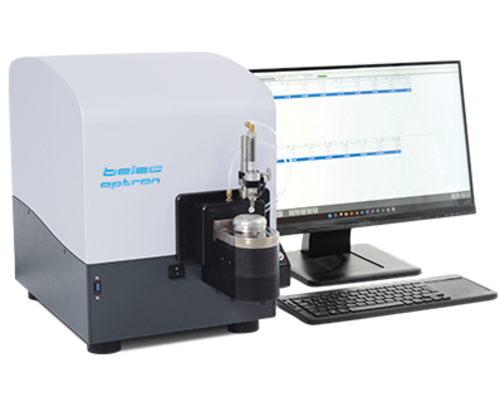

Belec OPTRON

The true all-rounder

Belec again raises the standards in the compact analyser class. The all-new model Belec OPTRON guarantees an unbeaten performance using a unique compact spectrometer design. It is used in the traditional foundry business as well as in incoming inspection or the recycling industry. Any metal processing company can take advantage of the very attractive price to performance ratio.

The Belec OPTRON is a true all-rounder: There are virtually no limitations as far the numbers of analytical programs is concerned, even with its small footprint the Belec OPTRON will surprise you with neat accuracy and precision.

- Multi-Matrix capable

- Plug-and play operation.

- Analysis in 10 Seconds

- Near Maintenance free operation

- Small footprint and weight

- Very cost effective

Belec IN-SPECT

True multifunctional wonder

With the completely redesigned metal analyser Belec again sets new standards. The all-new Belec IN-SPECT with its unique dual-spectrometer optics guarantees unbeaten performance in conjunction with significantly reduced maintenance costs in this instrumentation class.

It is used in the classic smelting control in foundries as well as in goods receiving, recycling or in regular quality assurance for production control.

The Belec IN-SPECT is a true multifunctional wonder:

Almost unlimited in the number of measuring programs, it fulfils almost every requirement combined with extremely attractive pricing.

- High performance ability due to the latest 7GSO System (7th Generation Spectrometer Optic System)

- Latest state-of-the-art detectors, developed for spectroscopy application.

- Compact construction

- Operator friendly design

- Low detection limits

- Excellent precision

- User-friendly software

- Free accessible sparking stand for larger or bulky samples

Belec Vario Lab

Precision and flexibility

Belec has entirely re-designed the well-established laboratory spectrometer.

The Belec Vario Lab again sets a unique standard in terms of precision and flexibility as it has been continuously improved in order to fulfil today’s needs for metal analysis.

It is – again- the most competitive in terms of flexibility as far as sample size and shape is concerned.

Next to the fixed sparking stand it can be equipped with an additional sparking probe.

- highest analysis accuracy and precision

- maximum long-term stability

- low detection limits

- virtually no limitations in terms of sample size and shape

- robust laboratory spectrometer

- flexibility through manifold equipping options

- free accessible sparking stand for larger samples

- integrated dynamic alloy database.

- base specific drift correction samples included.

- very low operating costs