Aluminium Metal Recyclers invests in Olympus Evident and Belec equipment to analyse materials

Aluminium Metal Recyclers have recently taken delivery of a new Olympus Evident Vanta handheld XRF, supplied by Innov-X Africa, a supplier of portable and handheld XRF elemental analysis instruments for metals and alloys, mining and geology, scrap and recycling, environmental and consumer safety, education and research and general manufacturing requirements in Africa

“We decided to invest in the two instruments because quality control is crucial when producing metals and alloys for use in harsh environments, as even small deviations from the intended composition can cause major issues and put lives in danger. From measuring surface temperatures to detecting impurities in molten metal, monitoring devices are keeping metal quality levels up and process and consumable costs down,” explained Mark di Pasquale, CEO of the Imritec Group.

“Luckily, there is also a range of methods that can be used to analyse materials, either in a lab or on site. On-site testing has the great advantage of giving the results quickly, and a popular choice is handheld X-Ray fluorescence. Handheld X-Ray fluorescence analysers verify materials quickly, reliably and cost-efficiently. They can identify a material’s elemental makeup within seconds, making it easier for manufacturers to select the right metal grades and tolerances for their needs. Such precision is essential for reliable part performance.”

“A spectrometer is an effective tool designed for precise and rigorous quality control testing services. Alloys are carefully designed for effective operation, machine compatibility and failure prevention. Many machine parts are vulnerable to failure if their chemical composition does not lie within a very precise set of parameters.”

“Aluminium Metal Recyclers (AMR) owns a processing facility which re-melts aluminium furnace dross, scrap and off-cuts generated by aluminium processors or fabricators, primarily in South Africa. The business was established in 2016 to fill identified shortfalls in recycling capacity and quality in the region.”

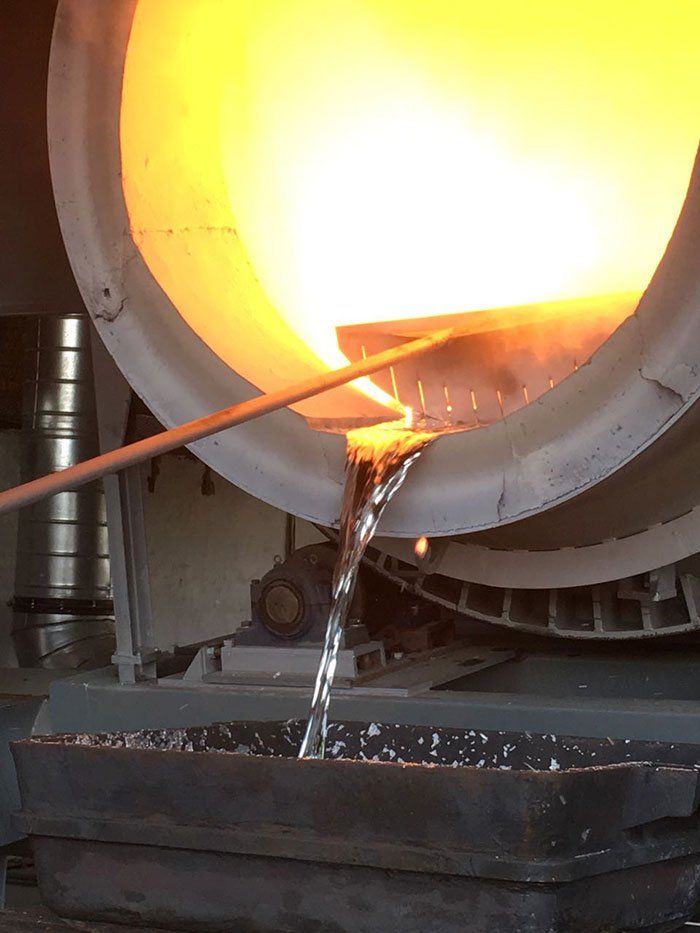

“AMR currently operates two furnaces at our facility in Pietermaritzburg, KwaZulu-Natal with capacity to process 1 000 tons of feed per month. The facility includes proprietary innovations to equipment and processes which reduce costs and improve recoveries. This technology forms the basis of the company’s growth plans. Recent equipment upgrades enable processing of higher margin scrap types to make ingot, cube and de-ox for both export and domestic markets.”

“AMR is currently processing dross from South32 and Isizinda Aluminium, which are both located in Richards Bay, KwaZulu-Natal, plus adhoc feed from other sources suitable for our rotary tilting furnace. We are investigating and trialling alternative sources of additional feed with higher margin potential, with some success already in conversion of scrap to ingot for the Japanese market.”

Aluminium Metal Recyclers (AMR) owns a processing facility which re-melts aluminium furnace dross, scrap and off-cuts generated by aluminium processors or fabricators, primarily in South Africa. The business was established in 2016 to fill identified shortfalls in recycling capacity and quality in the region

“All of the dross we process is returned to the supplier. The issue of melt loss and dross generation has a significant impact on aluminium processing facilities and the cost of operation.”

“The AMR site further houses our research and development centre and laboratory where continuous refinement and trials are undertaken to improve existing processes as well as develop the full cradle to grave recycling process. This is where the Belec In-Spect is housed. The table-top instrument combines most of the features of a complex laboratory instrument in a compact format. It is typically used in the classic laboratory situation in foundries, as well as in goods receiving, recycling or in regular quality assurance for production control.”

“AMR are part of the Imritec Group, which also includes Alumicor.”

“In early 2020 Imritec took a major step forward by acquiring its second aluminium dross and scrap re-smelting operation, the well-established Alumicor.”

“Alumicor’s plant is in Pietermaritzburg, KwaZulu-Natal, on a property owned by the Alumicor Group. It’s a highly strategic location, being next door to Hulamin, the largest aluminium semi-fabricator (rolling mill) in Sub-Saharan Africa.”

AMR currently operates two furnaces at their facility in Pietermaritzburg, KwaZulu-Natal with capacity to process 1 000 tons of feed per month. The facility includes proprietary innovations for equipment and processes which reduce costs and improve recoveries

“Alumicor has a contract to treat Hulamin’s aluminium dross, swath and scrap and the two companies have worked together for close to 15 years. They are connected by a direct private road.”

“The extensive experience of the Alumicor executive team includes involvement in the management of Alumicor operations since its inception in 2007.”

“Alumicor’s re-smelting plant features three oxyfuel-fired rotary tilting furnaces (two 10 ton furnaces and one 5 ton furnace), bag houses and associated raw materials and waste handling facilities. The rotary tilting furnaces are capable of processing up to 2 000 tons of aluminium dross every month, and there are plans to increase capacity even further by installing an additional 10 ton furnace subject to environmental approval.”

“Imritec’s core focus is on the recycling of aluminium dross, aluminium scrap and other aluminium waste products where it prides itself in achieving the highest aluminium metal recovery at the lowest processing cost per ton in the market.”

“The current Imritec operations collectively process approximately 36 000 tons of aluminium dross per annum which represents over 80% of Southern Africa’s available dross. This is testament to the robust and transparent relationships that Imritec has built over the years with dross generators, the majority of which are listed multi-national companies.”

“Imritec’s vision is to become a global leader in zero waste, cradle to grave recycling of aluminium dross and other aluminium scrap/waste products.”

“Aluminium is one of the world’s most recyclable materials, its original properties barely affected by the process. It is used in a huge variety of products including cans, foils, kitchen utensils, window frames, beer kegs and aeroplane parts.”

“Importantly, re-melting aluminium uses around 95% less energy than primary aluminium production from bauxite and alumina. So, from an environmental and economic standpoint, recycling is the far superior means to produce aluminium, with significant future potential.”

Aluminium Metal Recyclers have also recently taken delivery of a new Belec In-Spect arc-spark optical emission spectrometer also supplied by Innov-X Africa

“Imritec (Innovative Metal Recycling & Industrial Technologies) is building an aluminium recycling business to profit from this potential. This began with Imritec Limited’s (formerly Luiri Gold Limited, listed on the ASX) acquisition in December 2017, of Aluminium Metal Recycling (Pty) Ltd.”

Bahrain expansion

“2023 will be a pivotal year for Imritec as we commenced with construction of a full cradle to grave aluminium dross recycling plant in Bahrain, a market that is in dire need for a commercially feasible solution to their aluminium dross problem. The plant will have a 4 000 tons per month capacity and is expected to be producing product by Q4 2023.”

How Imritec makes more of aluminium recycling

“Imritec uses a ‘salt flux’ process when processing aluminium dross. The waste product from the melting operations is a black salt residue that contains many valuable by-products used in the steel, chemical fertiliser and cement industries, including flux for aluminium remelting. Currently our black salt is removed and processed by a third party. Imritec plans to invest, via JV, strategic alliances or outright in-house development, in a state-of-the-art black residue salt plant, creating a ‘closed loop’ where nothing is wasted and the facility will produce much of its own input flux.”