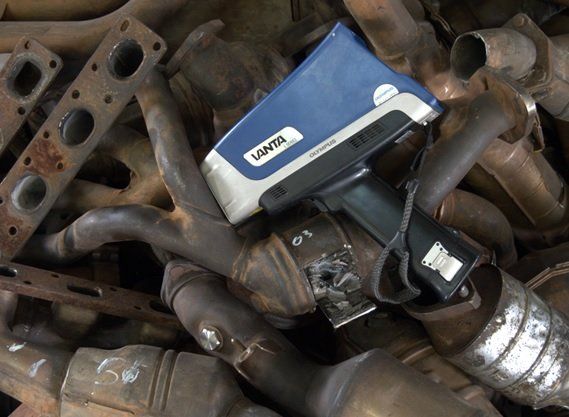

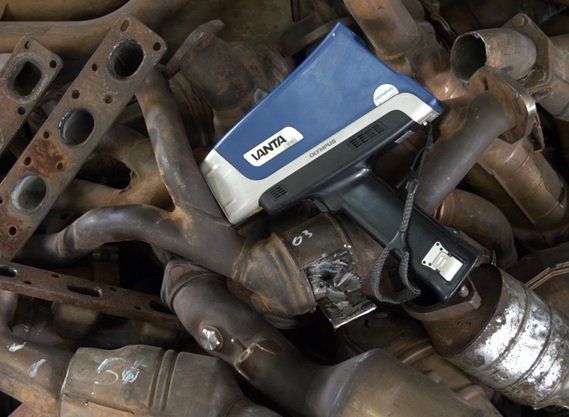

SELECTING THE RIGHT ANALYSER FOR YOUR APPLICATION

As a consumer, it can be difficult to understand the complexities surrounding the different X-ray fluorescence (XRF) analysers on the market. XRF analytical specifications can be confusing—for instance, you may have heard people talk about count rate, resolution, voltage, and tube watts, but you’re not sure of their significance. While these features all influence the price and performance of a handheld XRF analyser, what is most important is how they work together to achieve your objectives, without breaking the bank.

X-Ray Fluorescence Analyzer Detector Types: PIN or SDD?

There are two types of detectors used in handheld XRF analyzers: PIN and SDD. PIN detectors are an older technology that is less expensive, but also less sensitive than a silicon drift detector (SDD). Your answers to these three questions will help you determine if you need the sensitivity of an SDD.

Silicon Drift Detector Size

If you have decided you need the throughput, sensitivity, and elemental range of the SDD, most manufacturers offer a standard SDD and a large-area SDD. The large-area SDD has better analytical sensitivity but costs more. This can influence the price of your handheld XRF analyzer.

X-Ray Tube Anode Materials (Rh/Ag/W)

Some manufacturers carry a complete line of analyzers with a variety of available tube anode materials. Typical materials are rhodium (Rh), silver (Ag), and tungsten (W).

Silver

A good all-around anode material, silver is not as good as rhodium for magnesium or tungsten for cadmium but is a good compromise when you’re on a budget.

Tungsten

The use of tungsten or a similar heavy material is best for high-energy elements like cadmium, which is important for RoHS testing.

Rhodium

The best for measuring light elements. It’s particularly fast at measuring magnesium, a key element in aluminium grades, making rhodium the best choice for most alloy applications.